About 1 lithium metal battery

The term "lithium battery" refers to a family of different lithium-metal chemistries, comprising many types of cathodes and electrolytes but all with metallic lithium as the anode. The battery requires from 0.15 to 0.3 kg (5 to 10 oz) of lithium per kWh.

Lithium metal batteries arethat have metallicas an . The name intentionally refers to the metal as to distinguish them from , which use lithiated metal oxides as the.

Regulations forof batteries vary widely; local governments may have additional requirements over those of national regulations. In the United States, one manufacturer of lithium iron disulfide primary batteries advises that consumer.

Lithium batteries find application in many long-life, critical devices, such as pacemakers and other implantable electronic medical.

The computer industry's drive to increase battery capacity can test the limits of sensitive components such as the membrane separator, a polyethylene or polypropylene film.

• • • • •.

• • •

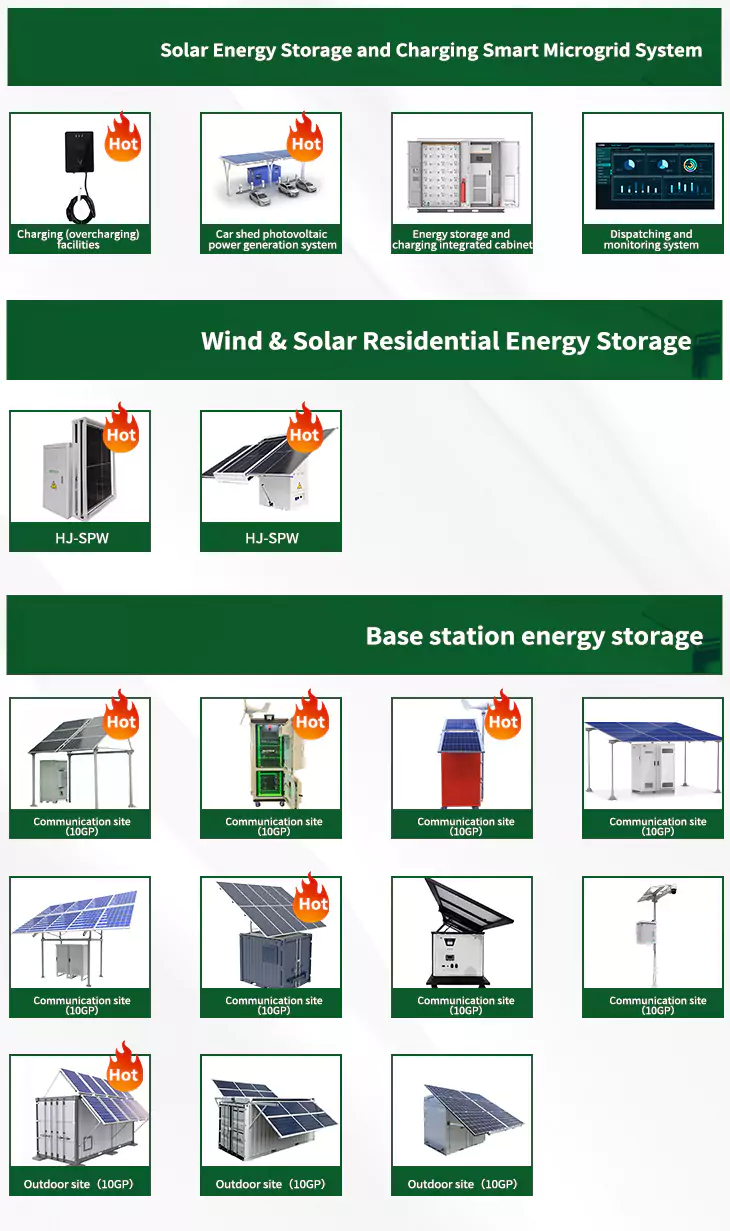

As the photovoltaic (PV) industry continues to evolve, advancements in 1 lithium metal battery have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient 1 lithium metal battery for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various 1 lithium metal battery featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Lithium metal hydride battery

- 1 lithium metal battery

- Lithium battery max voltage

- 60v lithium ion battery pack

- Lithium battery msds 2023

- Test lithium battery capacity

- 10 year sealed lithium battery operated smoke alarm

- How to charge 18v lithium battery

- Dewalt dcb107 lithium ion battery charger 12v 20v

- 24v 10ah lithium ion battery

- How to get a lithium battery out of sleep mode

- 7s lithium battery charger