About Silicon carbide photovoltaic cells

The symmetric samples and solar cells were fabricated with Czochralski grown n-type double-side textured, 170-µm-thick, 1 Ω cm silicon <100> wafers produced by LONGi. The wafers were cleaned i.

To be able to judge which HWCVD deposition parameter has a significant influence on.

The passivation quality of the layer was tested on symmetric samples and solar cells before ITO deposition by measuring the photo-conductance of the wafer using a Sinton WC.

The SIMS (time-of-flight-SIMS IV by IONTOF) measurement was conducted to analyse the interface properties of the nc-SiC:H(n)/SiO2/c-Si(n) stack, to investigate the correlat.

The high-resolution bright-field STEM images were obtained with a probe aberration corrected Hitach HF5000 microscope. EDX mapping of the O-K edge, Si-L.

The UPS system is a MULTIPROBE MXPS system from Scienta Omicron with an ARGUS hemispherical electron spectrometer and part of the JOSEPH cluster syst.To date, the use of 3C-SiC for photovoltaics has not been considered due to the band gap of 2.3 eV being too large for conventional solar cells. Doping of 3C-SiC with boron introduces an energy level of 0.7 eV above the valence band. Such energy level may form an intermediate band (IB) in the band gap.

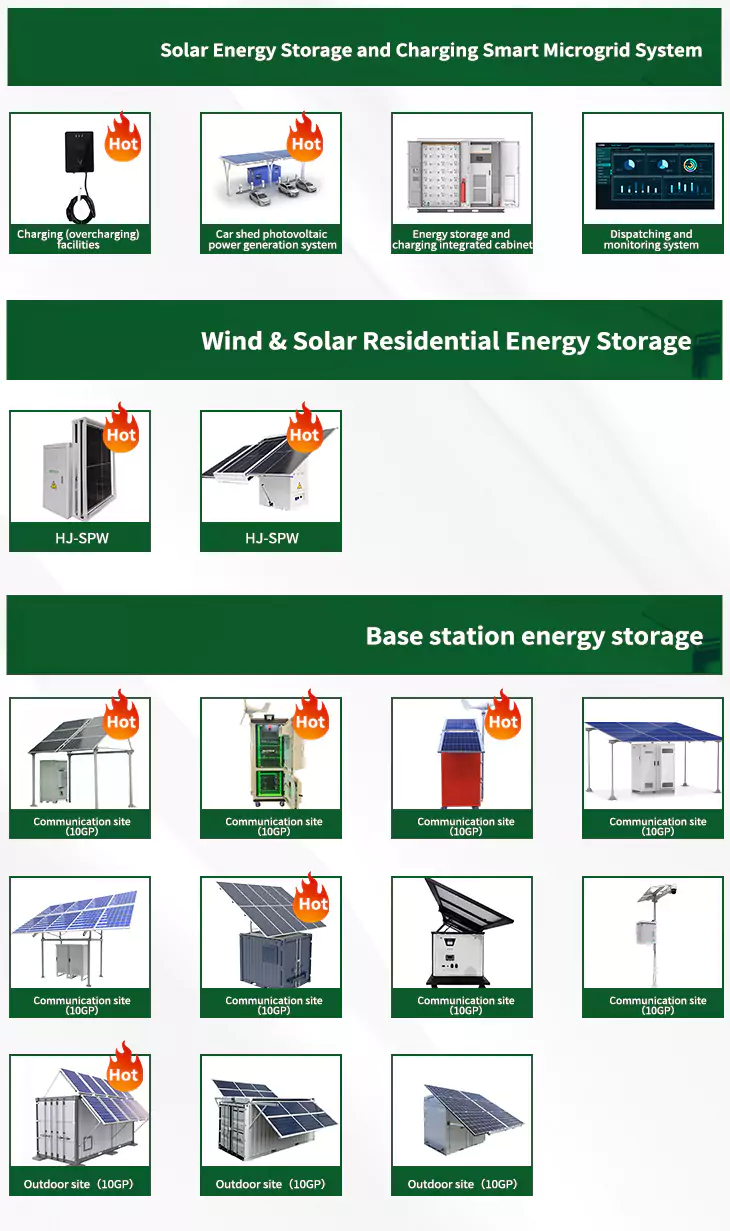

As the photovoltaic (PV) industry continues to evolve, advancements in Silicon carbide photovoltaic cells have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Silicon carbide photovoltaic cells for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Silicon carbide photovoltaic cells featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Crystalline silicon photovoltaic cells and products

- Silicon carbide battery vs lithium ion

- Silicon carbide solar inverter

- Amazon com asohi ke polycrystalline silicon photovoltaic charger

- Silicon photovoltaic cell applications

- Photovoltaic module crystalline silicon

- Perovskite on silicon tandem solar cells

- Photovoltaic silicon chip beneath

- Ceramic photovoltaic cells

- Solar photovoltaic cells development

- Very small photovoltaic cells

- How photovoltaic cells affect animals